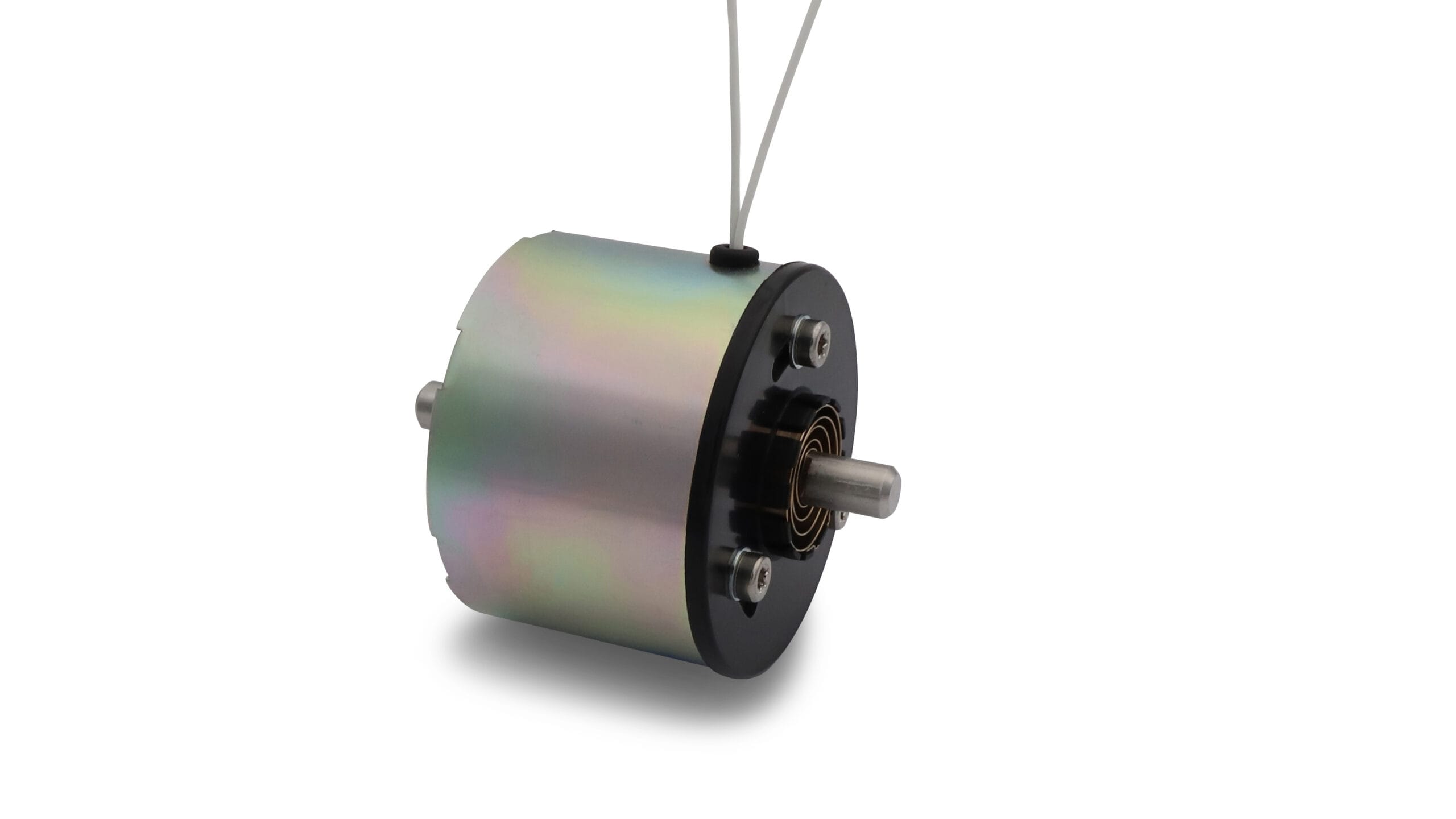

With the new series of stepper motors from the Italian company Ever Elettronica, Rotero offers a range of compact motors equipped with an incremental or absolute encoder. The highly accurate stepper motors have only limited heat development and therefore use little energy. In addition, the user benefits from broad functionalities such as speed, position and torque adjustment, an electronic reductor with an adjustable transmission ratio, and simple programming via the IDE e3PLC Studio programming environment.

Ever Elettronica was founded in 1977 and quickly became a leading company in the automation industry. In Italy as well as worldwide, Ever Elettronica delivers solutions complete with motion control for machines with stepper motors, brushless motors and drive mechanisms. The company also enjoys advising its customers to make the right choice for a specific application.

Quality, in-house knowledge, quick delivery, and a complete program make Ever Elettronica an excellent fit with Rotero. By now, their first stepper motors have reached Rotero’s warehouse, where these motors will be sure to find their way to machine builders, among other customers.

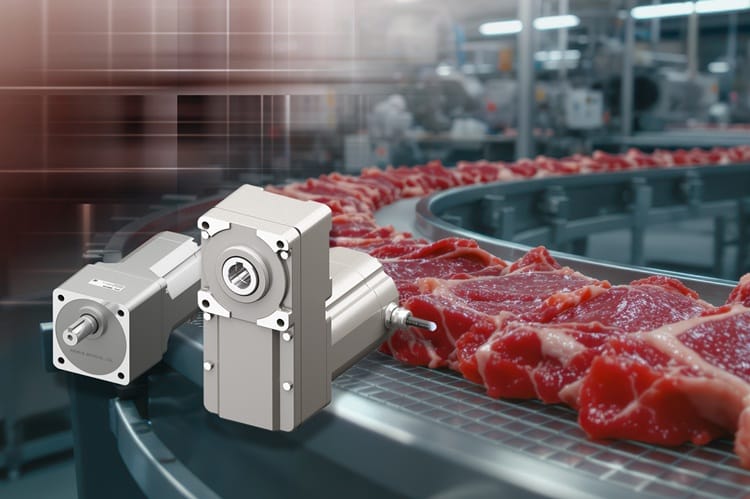

The compact PROFINET stepper motors — which have various closed-loop adjustment modes, including speed and position adjustment (homing, relative, absolute, and target, among others) — are receiving particular attention now. When the vector adjustment is used, motor torque remains constant so the motor runs very uniformly and at a low noise level.

In addition, the reliable compact motors are highly efficient (due to their limited heat development) and are equipped with several advanced security functions. These include integrated diagnostics, separate power supplies for logic and power, as well as error monitoring. Additionally, the stepper motors have an electronic reductor with an adjustable transmission ratio. Applications can be found in robotics, packaging machines, automation, domotics (home automation), security systems, and textile machines, among others.

Programming and configuration are easy due to the use of the SCI-service serial interface or CANbus in combination with the IDE e3PLC Studio programming environment. Ever Elettronica has developed an associated software kit for this purpose. Besides programming, this can also be used to execute a real-time debug, and each system can be viewed separately. Via the Master Controller, it is possible to control up to 127 motors simultaneously, with perfect synchronisation guaranteed by the powerful Motion Module.

Because of the communication via PROFINET, the motors can be integrated quickly and easily in a control system and they can be linked with Siemens products.