Designers and technicians know very well that trouble-free operation of the components within control panels and electrical cabinets depends on maintaining the correct ambient conditions within these enclosures.

At Fandis they understand this, which is why they offer a wide range of solutions to rectify, but above all to prevent, the most common problems experienced with electrical enclosures. You can read more about them in this post.

Temperature

One of the critical factors in electronic enclosures is the temperature: the combination of ambient temperature and the heat emitted by the components in the enclosure can potentially raise the cabinet temperature to higher than the specified operating range of components and circuitry. This in turn can cause protective shutdown or even failure, with the risk of production or service interruption.

The solution is to reduce the enclosure temperature by convection, whereby air enters and leaves the cabinet through two or more grilles at different heights, or by forced ventilation, using a fan mounted within the cabinet. For severe heat issues, air conditioning is another option.

Our solutions

Virdis: roof exhaust units and filters and filter groups

A range of roof exhaust units to expel hot air from the top of the enclosure, plus a range of filters and filter units for perfect ventilation of electrical enclosures.

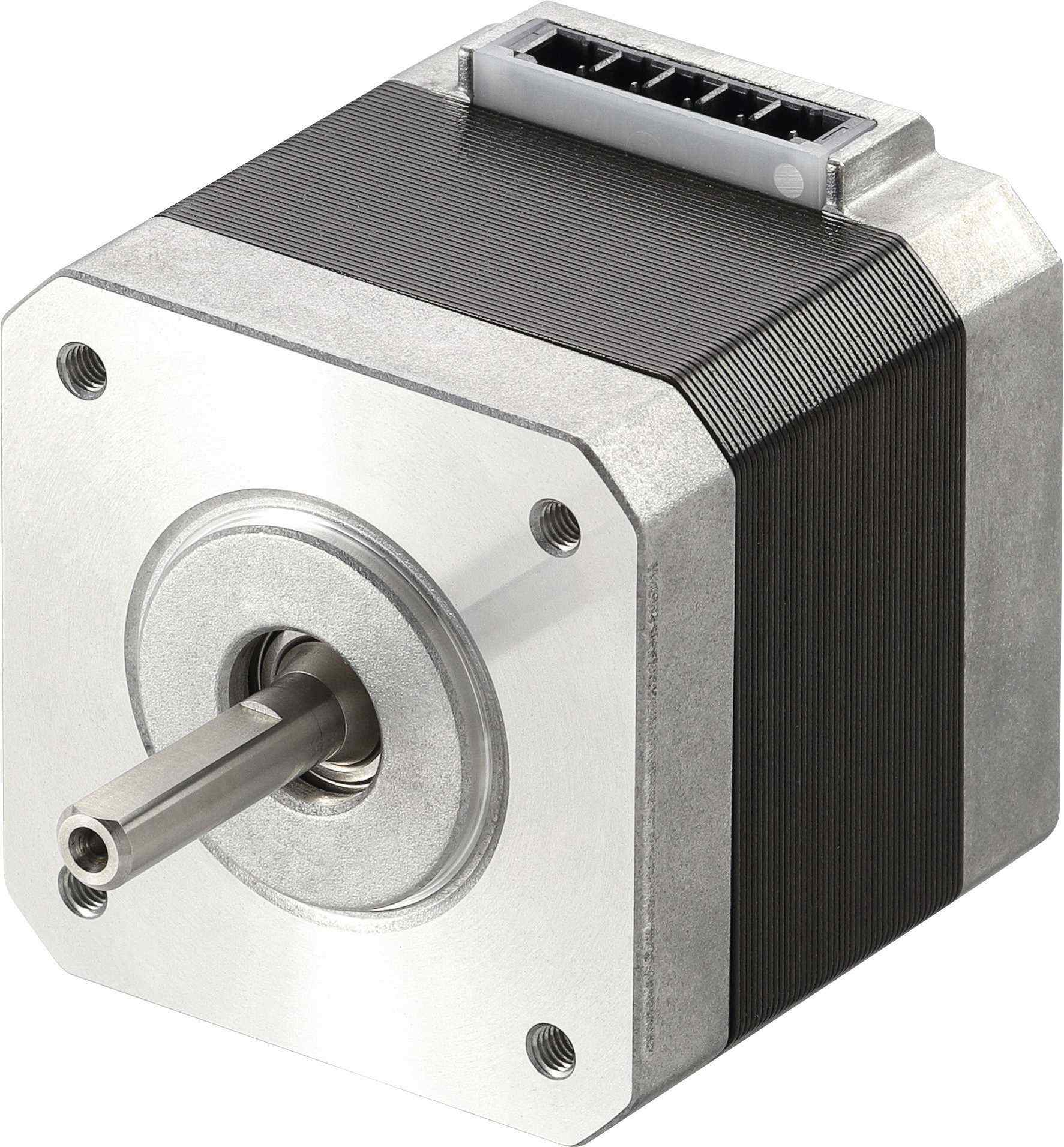

Bordos: Thermoelectric units

Standard and customised thermoelectric units for heating and cooling of small enclosures or electronic equipment in telecommunications and industrial automation. With no moving parts, these compact units are based on semiconductors that exploit the Peltier effect.

Condensation

A combination of air-conditioning and good ventilation: is this a sufficient solution for the protection of components and circuitry inside an electrical enclosure? Unfortunately, it’s not that simple. When we manage only the temperature, we actually expose the enclosure and its contents to the corrosive and oxidizing action of condensation and humidity. To solve this problem, the ideal solution is the combined use of both a thermostat and a hygrostat to control an anti-condensation element. This heats the interior of the cabinet, thus dissipating the moisture and preventing damage to the components within.

The severity of this problem depends largely on the ambient conditions and climate zone of the installation. The problem of humidity and condensation is greater in the tropics than in more temperate zones, where the drop in air temperature between day and night is less likely to reach the dew point at which condensation forms.

Our solutions

Orangis: thermostats and hygrostats

Mechanical thermostats and hygrostats for temperature and humidity regulation in electrical enclosures, with DIN rail mounting.

Fucsis: anti-condensation heaters

A wide range of heaters for temperature control within electrical cabinets, with cable or terminal block connection, plus DIN rail mounting. A variant with forced ventilation boosts heating capacity to as high as 400W.

Dust

We have now solved the problems of temperature and condensation. But what about dust? Obviously we can’t dust off the inside of an electrical cabinet the way we do our desks, but we also can’t ignore the issue of dust and the potential impact it has on the functioning of components and circuitry. Cabinets with forced ventilation are especially susceptible to the influence of foreign particles and dust from outside the cabinet.

Our solutions

Virdis: filters and filter groups

A complete range of filters and filter units to remove dust from ventilation air flows. On request, these filter products can be supplied to IP55 protection level, and fitted with EMC shielding.

Do you have other common problems or special requirements? Don’t hesitate to contact us – we have the solution you need!