NEWS: Rotero has a new supplier

NEWS: Rotero has a new supplier

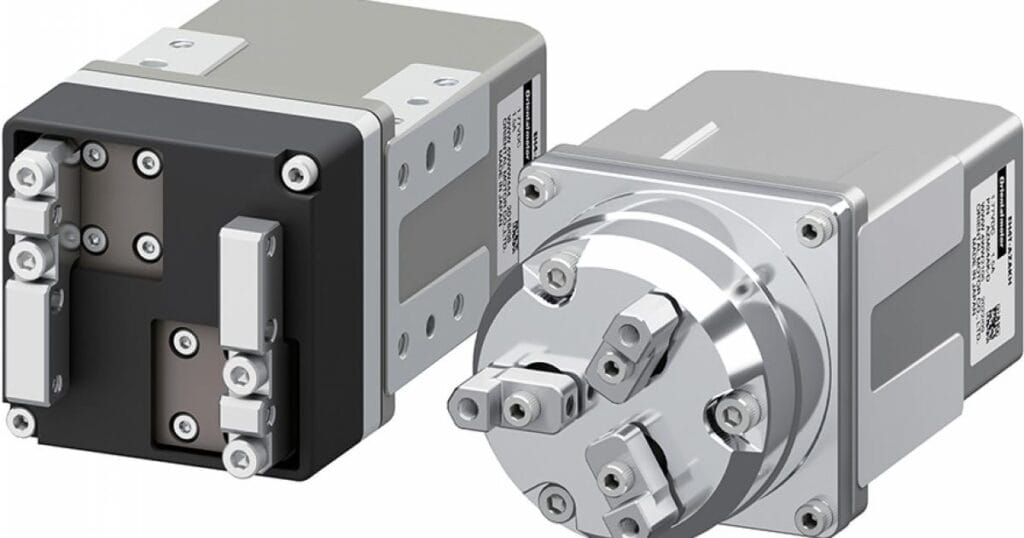

As the ‘hand’ of a robot or machine, the gripper plays a crucial role in industrial processes, such as on assembly lines and in robotics. Thanks to their precision and reliability, grippers contribute to more efficient production processes. Whether the process involves handling delicate parts in the electronics industry or heavy objects in the automotive industry, our grippers are the perfect solution for any automation application. Discover the versatility and performance of our grippers for your production environment.

A gripper is a mechanical device used to grasp, hold, move or manipulate objects in automated systems. It functions as the ‘hand’ of a robot or machine and is essential for numerous industrial processes. Grippers play an important role in automation, especially in applications such as assembly lines, pick-and-place processes and robotics, where they can accurately and reliably pick up and move objects. Grippers are an integral part of modern production environments, as they contribute to the speed, efficiency and consistency of these processes.

There are various types of gripper available. The most common types are pneumatic grippers, electric grippers and vacuum grippers. Pneumatic grippers use air pressure to generate grip and are ideal for heavy and fast tasks where robustness and speed are important. Electric grippers, on the other hand, offer greater control and precision, making them highly suitable for delicate applications, such as handling small parts in the electronics industry. Vacuum grippers use suction to pick up objects and are ideal for flat, smooth or delicate materials, such as glass or packaging.

The features of grippers make them highly versatile and suitable for a wide range of tasks. Grippers are designed to perform consistently and reliably in various working conditions. They offer adjustable gripping force, making them suitable for objects of different shapes and sizes and for different materials. Moreover, they are fast, which is essential for production processes where time pressure is a factor. Most modern grippers are equipped with sensors that provide accurate feedback, enhancing the precision and safety of the gripping action. This is especially important in applications where faultless execution is a necessity, such as in the medical or pharmaceutical industry. Grippers feature robust design and have a long service life, so they function reliably for extended periods, even in intensive production environments.

Grippers are used in many sectors and offer solutions for various challenges. In the automotive industry, for example, they are used to place parts accurately on the assembly line. In the electronics industry, grippers assist in placing small, delicate components on circuit boards. The food processing industry uses vacuum grippers to handle delicate products like fruit without damaging them. In the pharmaceutical sector, grippers are employed for precise handling of medicines and packaging, where hygiene and accuracy are necessary. The versatility of grippers makes them indispensable in almost every sector where automated processes play a role.

If you are looking for a reliable solution for gripping and manipulating objects in an automated environment, our grippers are the perfect choice. They offer the precision, speed and robustness you need to optimise your processes. Our grippers are flexibly deployable and suitable for various industries, from heavy industrial applications to delicate production processes. Moreover, they are designed to last and require minimal maintenance, allowing you to rely on their performance in the long term. Choose Rotero’s grippers and experience the benefits of precision, efficiency and reliability in your automation processes.

With these cookies, we and third parties can collect information about you and your internet behaviour, both within and outside our website. Based on this, we and third parties adjust the website, our communication, and advertisements to your interests and profile. You can read more information in our cookie statement.

If you opt for acceptance, we will place all cookies. If you opt for rejection, we will only place functional and analytical cookies. You can adjust your preferences at a later time.

With these cookies, we and third parties can collect information about you and your internet behaviour, both within and outside our website. Based on this, we and third parties adjust the website, our communication, and advertisements to your interests and profile. You can read more information in our cookie statement.

Functional cookies are essential for the proper functioning of our website. They allow us to enable basic functions such as page navigation and access to secure areas. These cookies do not collect personal information and cannot be disabled.

Analytical cookies help us gain insight into how visitors use our website. We collect anonymised data about page interactions and navigation, enabling us to continuously improve our site.

Marketing cookies are used to track visitors when they visit different websites. The goal is to display relevant advertisements to the individual user. By allowing these cookies, you help us show you relevant content and offers.