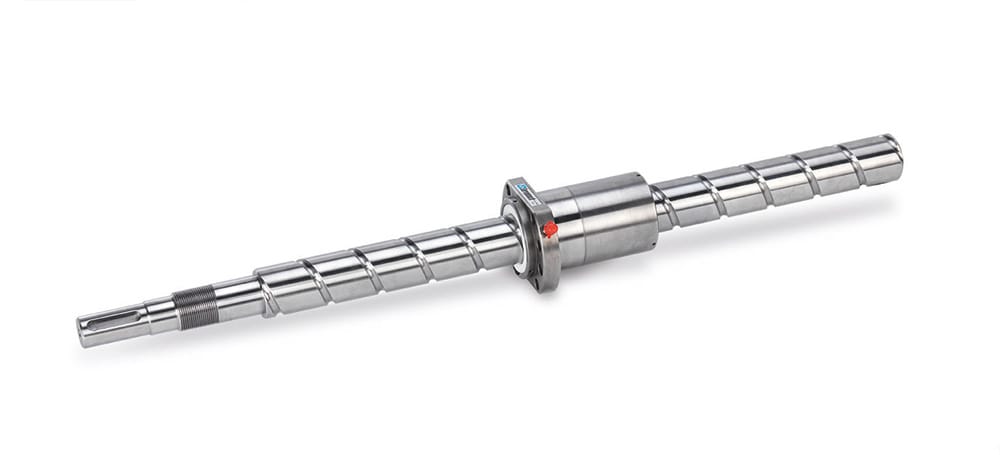

(Ball screw) Ball screw and travelling nuts

Servomech manufactures ball screws using state-of-the-art technologies such as 3D modelling software, precise quality measurement during the process and CNC machine tools, which are continuously updated. Through this approach SERVOMECH is able to offer customers guaranteed high quality and excellent service.

The SERVOMECH ball screw product range is extensive thanks to the numerous combinations of diameter, lead and the production process. Available on request: ball screws to ISO IT3 or IT5 accuracy classes, depending on the application requirements; Ball nuts without backlash or preloaded.

The Servomech ball screw and nut units are high-quality linear drive systems. They are ideal for industrial and automation applications in general and are used in highly diverse sectors, such as machine tools and industrial machines, injection moulding machines, presses, automatic production and assembly lines, assembly devices for electronic components, medical equipment and precision instruments.

They can be used as positioning screws, integrated into systems that require great stiffness, high positioning accuracy and repeatability. Another use is as a transport screw, where they are used to move a specific load without specific positioning requirements. In addition to the extensive production range available in the catalogue, Servomech can also build bespoke solutions based on the specific application needs of the customer.

Details

Available in various accuracy classes (ISO IT3, IT5, IT7)

Nominal diameter d0 [mm], in accordance with ISO 3408 and DIN 69051 standards:

14, 16, 20, 25, 32, 40, 50, 63, 80, 100, 120

Lead Ph [mm], in accordance with ISO 3408 and DIN 69051 standards:

4, 5, 6, 8, 10, 12, 15, 16, 20, 25, 32, 40

Max. thread length up to 10 m (depending on the diameters and the length of the rod).

Available without backlash or preloaded

Various dimensions available (DIN 69051, customer specifications or SERVOMECH design)

Materials:

Induction-hardened shafts: alloy steel 42CrMo4 or 50CrMo4 (UNI EN 10083-1), quenched

Hardness of ball tracks within the range (58 … 61) HRc

Ball nuts: alloy steel 18 NiCrMo5 (UNI EN 10084), hardened surface hardness

of contact surfaces within the range (58 … 61) HRc

Ball recirculation elements: alloy steel, hardened, with a surface hardness of (50 … 55) HRc or plastic depending on the application requirements

Operating temperature: (-20 … +110)°C

Higher temperatures of up to 500°C are possible, but require the use of special materials.

Other series within this product group

Request advice without obligation